Business Challenge

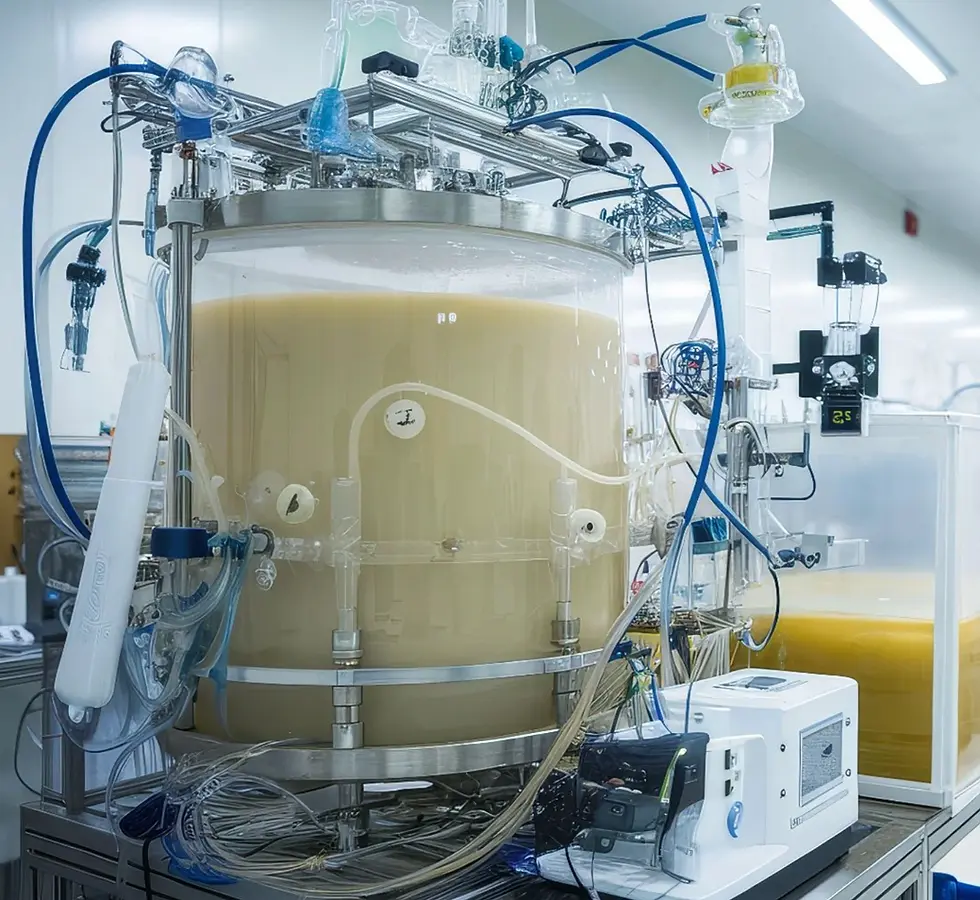

Foam formation during bioreactor operation is a known issue in upstream bioprocessing. As cells multiply and gases are introduced into the reactor, foam can develop unpredictably — potentially affecting oxygen transfer, sensor readings, sterility, and even triggering batch loss if not addressed promptly.

Traditionally, foam is managed reactively, with manual visual checks or time-based antifoam dosing. However, these approaches are:

Inconsistent and labor-dependent

Prone to late detection and overcompensation

Ill-suited for 24/7 monitoring across multiple reactors

In many production settings, bioreactors operate unattended for extended periods, with multiple units running in parallel. This creates a pressing need for automated, reliable, and scalable foam detection — without intrusive instrumentation.

The Graypaw Solution:

GrayVisions for Foam Monitoring

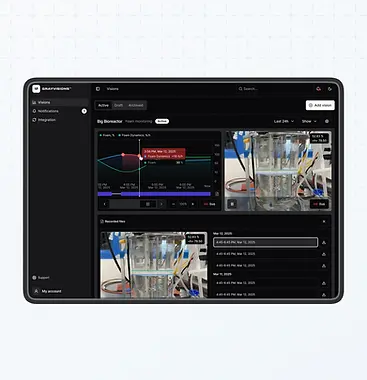

To meet this challenge, GRPAW and Proconex implemented a vision-based foam monitoring solution built on the standard GrayVisions platform.

Designed for edge deployment and multi-camera environments, the system continuously monitors visual foam levels in bioreactors — without modifying reactor hardware or inserting probes.

Core capabilities:

AI-powered cognitive vision pipeline detects foam presence and dynamics in real time

Each camera feed is processed independently on an edge device running GrayVisions

Alerts are triggered when foam exceeds defined thresholds

Historical video, annotations, and event logs are stored for review and QA

Operator-facing UI provides live feed, overlay indicators, and alert summaries

This solution supports both desktop-scale bioreactors (for lab or pilot use) and full-scale production tanks, enabling seamless integration across process scales.

Deployment Architecture

GrayVisions was deployed as a modular edge-based system, where one device handles multiple bioreactor camera streams in parallel. This reduces hardware footprint while enabling flexible coverage — especially in clustered bioprocessing suites.

All validation and prototyping were conducted in collaboration with the Jefferson Institute for Bioprocessing, where real fermentation conditions allowed for precise tuning and testing of cognitive models.

Outcome

Delivered reliable, real-time foam detection with no physical integration required

Enabled early corrective action via automated alerting

Reduced reliance on manual checks and time-based dosing

Validated system performance in lab and near-production environments

Scaled efficiently across multi-reactor setups using shared edge hardware

“This use case shows how cognitive vision can deliver tangible process control — with zero sensor footprint.”

Customer

Our latest blog posts

Discover the latest insights, trends, and news from our expert team.